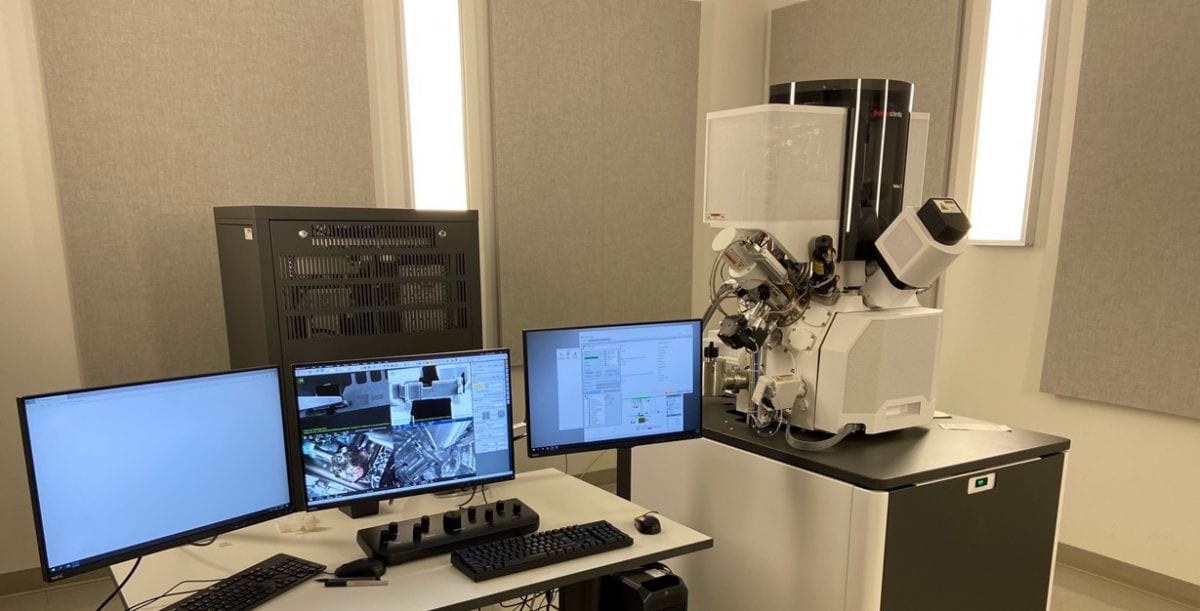

SEM & FIB: Cross-sections, patterns, TEM lamella sample prep & liftout & elemental information

Thermo Scientific focus ion beam (FIB)-Helios 5 CX dualbeam is equipped with highly automated, multisite, fastest and easiest sample preparation for S/TEM.

The key features are:

- In SEM mode, extreme high resolution (1nm) at low acceleration voltage and 0.6nm at 15kV.

- In ion beam mode, 4 nm resolution for 30kV.

- Acceleration voltage for SEM range from 100V-30kV.

- Acceleration voltage for ion beam range from 500V-30kV.

- Auto-slice&view and 3-D reconstruction through Avizo software

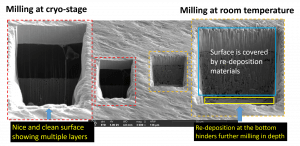

- Cryo-stage from Quorum for beam-sensitive sample

- EDS detector for elemental analysis

- 10 types of electron/ion detectors/cameras

- Elstar in-lens SE/BSE detector (TLD-SE, TLD-BSE)

• Elstar in-column SE/BSE detector (ICD)*

• Elstar in-column BSE detector (MD)*

• Everhart-Thornley SE detector (ETD)

• IR camera for viewing sample/column

• High-performance in-chamber electron and ion detector (ICE)

for secondary ions (SI) and electrons (SE)* - Thermo Scientific In-chamber Nav-Cam Camera for sample

navigation* - Retractable annular ring-like ABS detector

• Retractable, low-voltage, high-contrast, directional, solid-state

backscatter electron detector (DBS)*

• Retractable STEM 3+ detector with BF/ DF/ HAADF

segments*

To request training or reserve time on this instrument, click here to go the Thermo Helios 5 CX equipment page on SUMS.

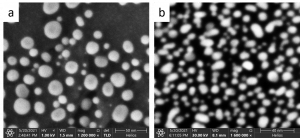

(a) SEM image of Au nanoparticles at 1 kV. The spatial resolution is <1nm. (b) STEM image of nanoparticles. The spatial resolution is <0.4nm.

System Details:

The Thermo Helios 5 CX combines a high-resolution Schottky FEG-based scanning electron microscope (SEM) with a high-energy Focused Ion Beam (FIB) using Gallium-69. The system can accommodate circular samples up to 50mm in diameter and approximately 20-25mm tall (the stage has about a 25mm Z-travel).

The SEM operates up to 30kV with seven calibrated current levels for any given accelerating voltage. The aperture current levels are set at various accelerating voltages (from 200V to 30kV). The SEM has an Everhart-Thornley detector (ETD) and an in-lens detector (Through-Lens Detector (TLD)). The TLD can be biased in multiple modes and can provide both secondary and backscatter images. It features an Ultra-High Resolution immersion mode (Mode II) that can yield higher resolution pictures for some types of samples and can be used in four modes (Secondary, Backscatter, Charge Reduction, and Down-Hole Visibility). Typically imaging is done with the TLD.

The FIB typically operates at 30kV (operating from 500V to 30kV) and has 13 calibarated current levels. The ion beam is typically used to remove material from substrates (e.g. milling cross-sections or arbitrary simple shapes) and can be used to deposit tungsten or Naphthalene carbon (from an organo-metallic precursor) locally via needle (so called GIS – gas-injection system). The system can mill bitmaps up to 512 x 512 size in grayscale, although getting optimal features requires optimization. When the ions hit the sample, they generate secondary electrons and ions from the collisions. Those ions and electrons are then used to form the “ion beam” image using the ICE detector.

The combination of the SEM and the FIB allows for milling cross-sections using the FIB and imaging the resultant area with the SEM. The system also has EDX (energy dispersive X-ray spectroscopy) for determining the chemical composition of samples and forming maps of surface and cross-sectional composition. This system was installed Auto-slice and view software which allows to acquire both the SEM image and EDS map in each step of milling. The software can also correct the image drift in Y direction.

Click to display ASV- SEM stack

Click to display ASV- EDS map stack

Red: Al-Ka, blue: Si-Ka, white: Zr-Ka, Geen and yellow: Ga and carbon which mixed together as a result of deposition of the top buff layer.

TEM lamellas can be prepared using the FIB and lifted out using the easy-lift nanomanipulator. Thermo programs called Auto-TEM can autonomously prepare multiple lamellas for liftout.

The system is installed the Quorum cryo-holder for investigating soft materials such as bio-materials and polymers. The cryo-stage running at -140 C will significantly decrease the beam effect on the materials.

The chamber has electrical feedthroughs to allow for in-situ characterization. Several professors have used this platform for their work, including in-situ tensile testing.

Typical applications include materials characterization, structural testing, photonic device prototyping (via bitmap), and circuit editing. The staff has extensive experience with various applications and provides regular, comprehensive training on the instrument.